Extinguishers: Periodically Checking Extinguisher Gauges is Critical for Safety

A stored pressure fire extinguisher is the most common type of extinguisher. It has both the extinguishing agent and the pressurizing gas within the same container (cylinder). You can quickly identify a stored pressure dry chemical extinguisher because it has a pressure gauge. As the gauge indicates, a stored pressure extinguisher is ready for use if it contains an agent and is sufficiently pressurized. Here’s what needs to be checked to ensure the reliability of extinguisher gauges.

Examine the Gauge

Extinguisher gauges typically do not fail. An extinguisher gauge is replaced when damage is observed or upon discovery that the wrong gauge has been installed on an extinguisher. On an annual basis, as required by NFPA 10, 7.3.2.1, the extinguisher technician performs a thorough examination of every extinguisher in service, including the following extinguisher gauge checks:

- Verifies the gauge cover is not cracked, broken, or “smoked” (sun, heat, or corrosive damage).

- Verifies the gauge needle is in the operable range (green zone).

- Verifies the rated operating pressure of the gauge corresponds with the nameplate pressure.

- Verifies the agent type on the gauge face corresponds with the agent used in the extinguisher.

- Verifies the gauge threads are compatible with the valve body material.

Check the Charging Pressure

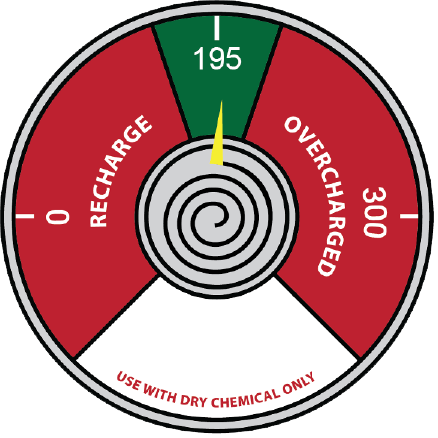

The extinguisher gauge pressure must match the charging pressure. If the charging pressure for the extinguisher is 195 psi, then the gauge has “195” printed in the green area. You can find the extinguisher charging pressure on the nameplate or the service manual.

Check the Agent Type Marking

Extinguisher gauges are marked with the type of agent. A dry chemical gauge will say, “USE WITH DRY CHEMICAL ONLY.” A gauge with the marking “USE WITH WATER, AFFF OR LOADED STREAM ONLY” can be used with any of these three agents. Never install a gauge that does not match the extinguishing agent within the extinguisher.

Verify Gauge Compatibility with Valve Body Material

Check the gauge manufacturer’s code letter before installation to ensure valve body compatibility as follows:

- Aluminum – A line above the gauge manufacturer’s code letter matches an aluminum valve body.

- Brass – A line below the manufacturer’s code letter is a gauge for use with a brass valve body.

- Aluminum or Brass – A universal gauge has lines above and below, or any line is absent.

Use the Right Tool

An extinguisher gauge is a critical component of a stored pressure extinguisher. Understanding what needs to be checked offers a reasonable assurance that the gauge will provide accurate readings, and that the extinguisher will be ready for use during a fire emergency.

Use the Right Tool

The proper tool for removing and installing extinguisher gauges is the Brooks Gauge Wrench (P/N GWRENCH). It’s specifically designed, and if used correctly, it will not damage the gauge or the extinguisher valve.

An extinguisher gauge is a critical component of a stored pressure extinguisher. Understanding what needs to be checked offers a reasonable assurance that the gauge will provide accurate readings, and that the extinguisher will be ready for use during a fire emergency.